The bottom of this channel had to be dewatered to allow pipeline inspection. Three drill points have been located, but water on site is preventing the use of ground penetrating radar.

The AquaDam® and equipment used to install it were packed in on foot by workers. No vehicles were required for this project.

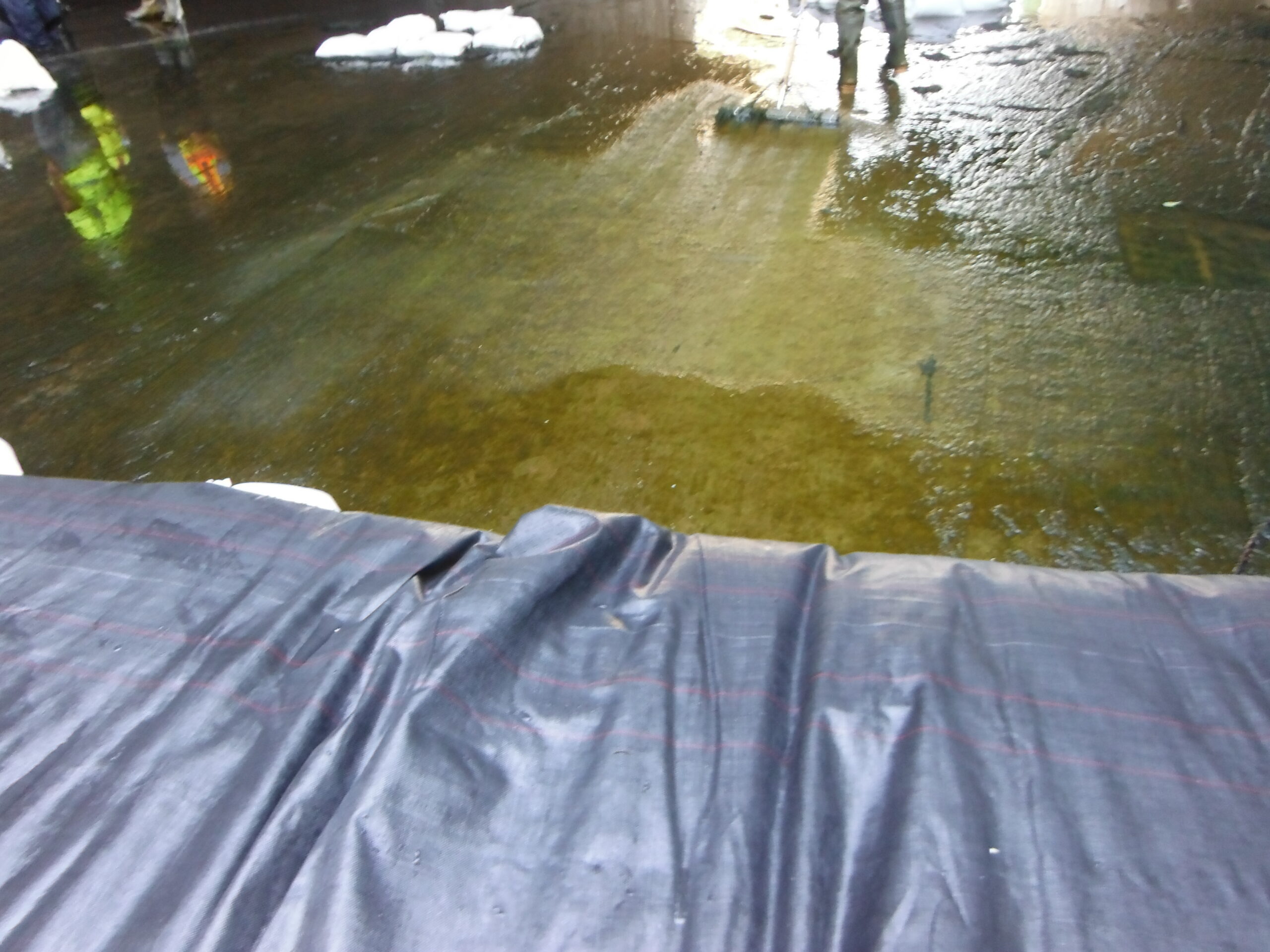

The 30-inch-tall by 154ft long SCE AquaDam® has been partially unrolled exposing the fill tubes. Behind the AquaDam® sits the generator and electric used for filling.

The fill-tubes and starting point must be elevated higher than the maximum height of the filled AquaDam® (30-inches in this case) to keep the water inside of it. Scrunching the AquaDam® material in to the 90-degree angle of the concrete wall will help provide a better seal, prior to filling.

Both sides of the starting point of the AquaDam® have been tied up and back to the fence post above the concrete channel, which is approximately 20ft above the channel floor.

The larger diameter hose is being fed into the fill-tube closest to the work area or on the downstream side.

The starting point (or the open end) of the AquaDam® has been lifted, supported, and stabilized using these ropes that are tied back to fence posts at the top of the channel wall.

While the AquaDam® was filling water began passing over it, so sandbags were used to keep the unit in place and for support.

Each of the fill-tubes now have a hose (connected to pump) in them and are filling with water. Notice that the starting point (open end) of the AquaDam® is elevated higher than 30-inches.

The pumping station for this job started with a generator, two electric sump pumps with hoses, a strainer basket, and milk crate to elevate the generator out of the water.

This strainer basket was used to help keep wildlife, debris, and clumps (that may be in the canal) out of the pump intake.

Pumping power will govern the time it takes to fill an AquaDam.

The majority of this AquaDam® still remains rolled up, which allows for the unrolled portion to fill and form head above the surrounding water.

The downstream fill-tube (with the larger discharge hose) is filling faster than the upstream side. Now that part of the AquaDam® has head, the upstream water has begun to back up enough so that the smaller pump can draw and fill the upstream fill-tube. Pumps should be adjusted appropriately to keep both sides equal while filling in flowing water.

Both fill-tubes are roughly the same height now, and a head pressure (inside the AquaDam) has begun to unroll the AquaDam. Applying pressure to the the outside of the roll (as the AquaDam® fills) allows the unrolled portion keep head above the surrounding water.

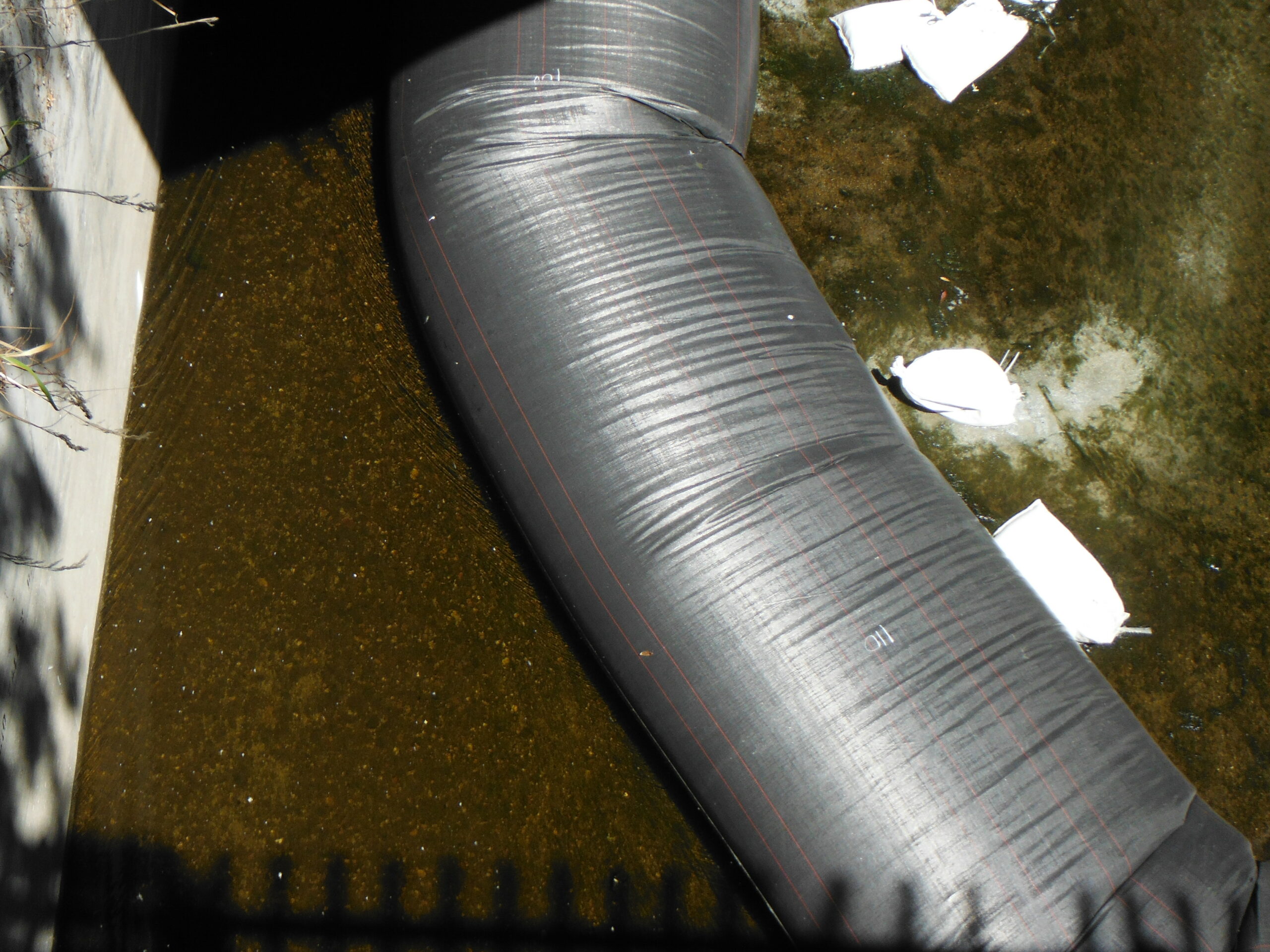

A pleat is made on the downstream side of AquaDam® is made to allow the roll to rotate forming the turn needed. The pump filling the pleated side is typically turned down until after the turn is made.

Upstream water is backing up and rising. The contractor’s consultants have accounted for this rise prior to ordering the AquaDam, hence a 30-inch tall AquaDam® that controls a maximum of 24-inches of mud/water depth.

Sandbags have been placed as backup support for the AquaDam, while it is filling.

For this job one of the drill points (surrounded by sandbags) is only approximately 11ft from the wall. The 30-inch tall AquaDam® will be 6ft wide when fully filled. Once the AquaDam® goes around the drill point, the distance between the AquaDam® and the canal wall only leaves a few inches of width for the water to pass through.

The AquaDam® continues to fill, creating a head above the surrounding water.

Head inside the AquaDam® lowers as the length is unrolled. Too much length was let out while making the first turn and the upstream portion of the AquaDam® experienced head loss resulting in a slight rolling action, seen here.

Workers rolled the extra length back upstream allowing head to form once again in the upstream portion of the AquaDam.

Workers hold the AquaDam® roll end so that the unrolled portion gains head pressure.

Creating a starting bank for a SCE AquaDam® sometimes takes creativity. Ropes and anchoring points worked well for this job.

All the flow has now been forced between the AquaDam® and the wall creating a much narrower channel. This pinching of the flowing water causes the upstream water to rise and the velocity in the new narrow channel to increase.

Looking downstream we can see the flowing water has gained head and is looking more turbulent than before.

The AquaDam® continues to fill, while workers allow the unit to unroll slightly keeping the desired head above the surrounding water. The work area has been partially isolated, with minimal seepage from the upstream portion of the AquaDam® cofferdam.

The work area has begun to dewater.

The AquaDam® continues to fill creating a stable yet flexible cofferdam system.

The project manager for this job said, "I would gladly pay five times what I paid for this AquaDam, because it saved me 100 times the cost."

The AquaDam® has been turned again back towards the same wall it started on, creating a horseshoe or “U” shape configuration.

The AquaDam® has almost reached the ending bank, completely isolating the work area from the surrounding water.

There was not a lot of space between the AquaDam® and the opposing canal wall, but there was just enough.

The AquaDam® cofferdam system looking upstream.

It is important to abut into the ending bank at a 90-degree angle. This will help to stabilize the column of water (inside of the AquaDam) as it climbs the vertical bank. After marrying up to the ending bank the closed end or the roll should be secured, so that it cannot move.

The work area has been completely isolated, and the AquaDam® can now be filled until it is full.

Here are the three locations in the work area that will be investigated, they are the spots surrounded by sandbags.

Sandbags were used here to help support the starting bank (open end) of the AquaDam® during filling.

The AquaDam® is in place and filling, while workers prepare the work area.

The water depth has risen upstream and the velocity flowing through the gap (between the edge of the AquaDam® and the wall) has increased.

Workers taking a break while the AquaDam® continues to fill.

Here we can see the narrow gap that the channel was reduced to. Notice the ripples on top of the water in the gap, this indicates the water here is moving fast (increased velocity).

The water depth in the work area has been reduced to a few inches.

The length of the AquaDam® remaining rolled up, sits on top of the inflated portion of the unit at the ending bank. Typically, this roll end would be tied back to anchor points, for stability.

The AquaDam® continues to fill. The size of the pumps used to fill an AquaDam® will determine speed at which the unit will be filled and should be considered prior to ordering.

Sandbags were placed on the downstream side of the starting bank here to support the open end of the AquaDam® at the 90-degree corner.

The upstream water depth became so high that the generator running the pumps needed to be raised. A spare unused AquaDam® was up for the job

As the AquaDam® continues to fill, eventually the upstream water depth and increased velocity in the narrow gap will stabilize.

The AquaDam® cofferdam system is working great! Look at the water depth differences from the left (work area) and right (upstream) of the AquaDam.

Looking downstream at the ending bank, where the AquaDam® closed off the work area.

Sandbags have been placed on the rolled-up length of the AquaDam® to help prevent the roll from unrolling.

The sandbags did work very well at preventing the rolled-up length from unrolling.

The unfilled/empty width of an AquaDam® is wider than the filled/full width. Notice the AquaDam® is barely touching the sandbags now.

The AquaDam® became overfilled and can be seen leaning to the left. This leaning is due to a lack of tie-offs needed to restrain the rolled-up length from unrolling.

After continuing to fill, the leaning produced a non-standard unrolling action that introduced a twist in the AquaDam. Water will always go to the lowest point. The remaining length of the AquaDam® unrolled and the unit continued to fill.

The work area remained isolated after the extra length unrolled. The AquaDam® slightly dropped in height, so additional pumping was required to bring it back up to 30-inches.

Looking upstream, we can see the closed end of this single closed end (SCE) AquaDam.

Workers have begun dewatering the work area, removing built-up seepage. When using cofferdams seepage is inevitable and typically must be addressed.

The AquaDam® continues to fill.

Workers use a shop vac in conjunction with the sump pump to dewater the work area for this job.

Workers dewatering the work area.

As the AquaDam® fills it is forming a tighter seal against the concrete wall, isolating the work area from the surrounding water.

Looking down on the narrow gap in the flow created by configuration of the AquaDam.

A photo of the rope anchoring used to support/stabilize the AquaDam® at the starting bank or open end.

Upstream of the AquaDam® showing water outside of the cofferdam and the work area drying.

The ending bank where the AquaDam® was place is working great, even though the extra length rolled downstream.

The work area has begun drying up in the sunlight.

Workers are brushing the remaining water towards the pumps to prep the work area.

Looking downstream from inside the work area, notice the flow of the canal is all outside of the AquaDam® cofferdam system.

A photo looking upstream of the cofferdam system. AquaDam® is doing an excellent job.

30-inch tall 6ft wide (fully filled) 154ft long Single Closed End (SCE) AquaDam, Partial Canal Dewatering, Rectangular Concrete Canal, Stream Diversion