Gray Rocks Dam, Wyoming 16ft tall, 300ft long AquaDam® installed to isolate gates for painting activities. The work area was not completely dewatered, but only drawn down to a level below the bottom of the gates to be worked on. This minimized the hydraulic forces imposed on the AquaDam.

16'x300' long AquaDam

Gates (black) with a new coating of paint.

Before Installation

Rolled AquaDam® placed at waters edge. For a more practical, safer, installation, the AquaDam® should have been placed at the shelf halfway down the slope, and unrolled into the water from that point. This would result in a flat work area at the start of the dam, greatly reducing fall/trip risks.

Getting the first roll of dam unrolled.

Fill Tubes and Open End of AquaDam® have been pulled up the bank. Hoses have been inserted, and pumping/filling of the dam has begun.

Fill Tubes and Open End of AquaDam® have been pulled up the bank. Hoses have been inserted, and pumping/filling of the dam has begun.

The end of the AquaDam® is tied up to the posts of the railing at the top of the bank. The ends of any AquaDam® should be tied up prior to filling, and remain tied up through the installed lifetime of the AquaDam.

The AquaDam® unrolls in a straight line as both inner chambers are filled with water at the same time and rate.

The unrolled section of AquaDam® presents a suitable foot traffic and work platform, even before the entire dam is filled, or even unrolled. Workers can walk to the end of the dam to tie ropes to the bottom seam of the AquaDam, exposed at the roll. These ropes, when pulled by people or equipment, can be used to reorient and re-align the AquaDam® during installation, before the dam is taller than surrounding water level.

16'x300' AquaDam® continues to unroll.

16'x300' long AquaDam® is almost completely unrolled, but has barely broken waters surface. At this point, the dam is subject to influence from external hydraulic differentials. This is not a concern on a controlled body of water like this reservoir, but should still be considered and planned for, as if there was water flow. Preventing problems from forming is a lot easier than trying to solve problems that have formed.

The 16'x300' long AquaDam® has reached waters edge at the far bank. Now, it cannot unroll without the whole dam growing in height.

The 16'x300' long AquaDam® begins to grow above surrounding water level.

The "Closed End" of the AquaDam® is tied up to anchor points at the top of the far bank.

16'x300' long AquaDam® has filled to a point that it is about 2ft higher than surrounding water level.

16'x300' long AquaDam® continues to grow in height. The water in the work area is being drawn down, using the (2) 3" pumps on top of the AquaDam. Drawing down the work area water level will induce a hydraulic differential across the dam, so the lake water will push the dam "uphill" towards the work area, keeping the dam in place as it fills.

16'x300' long AquaDam® has achieved its full height. Notice the tie off ropes holding each end of the AquaDam® up on the sloped bank.

The AquaDam® has stayed in place for about 2 months. The gates are painted (black color).

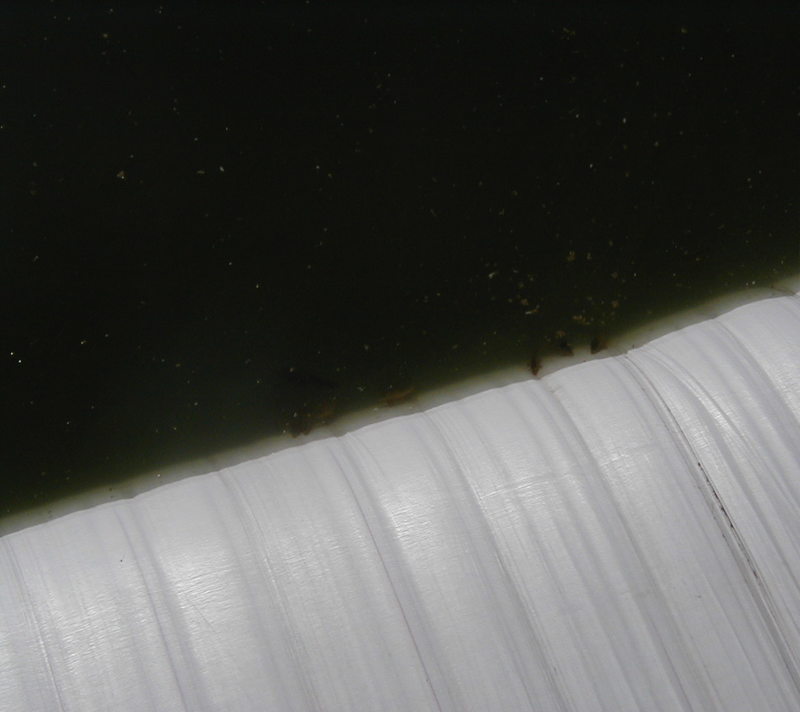

Close up of the 16ft dam in front of the newly-painted gates.

After 2 months, the side of the AquaDam® is covered with algae, which is grazed by the native fish.

More fish nibbling on the algae growing from the side of the AquaDam.

Detail of 16'x300' long AquaDam® installed in front of the gates of Gray Rocks Dam. (left)

Detail of 16'x300' long AquaDam® installed in front of the gates of Gray Rocks Dam. (right)

Overview of 16'x300' long AquaDam® installed in front of the gates of Gray Rocks Dam.

Full lake water on left side of AquaDam, partially dewatered work area on the right side of the AquaDam.

Overview of partially dewatered work area

A 16ft tall, 300ft long AquaDam® was installed upstream of the Gray Rock Dam Gates, to isolate the gates prior to anti-corrosion paint application.