Hurricane Harvey brought record rainfall to Texas. This record rainfall inundated all waterways, leading to erosion in many areas. A 16ft tall, 300ft long AquaDam, with 8ft tall support dams, was deployed to isolate the bridge and road areas, permitting dewatering for inspection and repair.

The starting bank for the primary 16ft tall AquaDam.

The ending bank for the primary AquaDam.

The 16ft tall primary AquaDam has been put into position (on the starting bank) so it can be deployed. Ropes are being tied to the starting point of the AquaDam to help secure the unit in place.

The primary AquaDam has been rolled down the starting bank, so that the fill-tubes can be accessed and the AquaDam can be filled.

Ropes have been placed under and back over the top of the AquaDam to help control it’s deployment across the body of water.

Workers are unfolding the fill-tubes so that discharge hoses can be placed inside and the AquaDam can be filled with water.

The fill-tubes must be bloused out enough so the someone can climb inside and place the discharge hoses far enough down the starting bank.

Duct tape was used at the end of the discharge hoses, so that no sharp edges would puncture or cut the internal plastic tubing while in use.

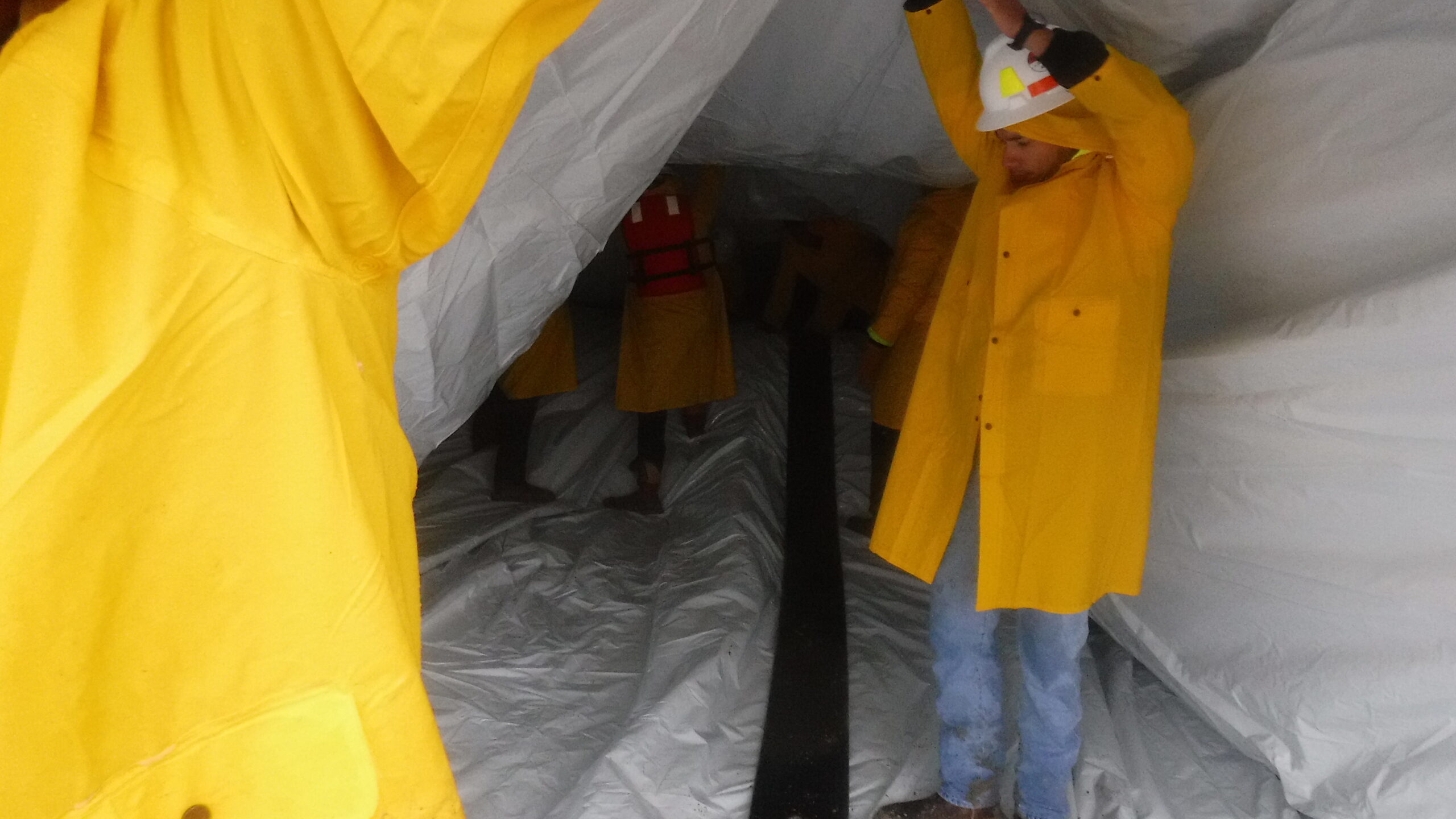

Workers going inside of the 16ft tall primary AquaDam's first fill-tube to place the discharge hose.

Another angle of the workers putting the discharge hose into the first fill-tube.

Now the second fill-tube is having a discharge hose placed in it.

Here is a view of the inside of the fill-tube, where the discharge hose is going. Notice the hose is going over and beyond the starting bank.

A worker is bunching up (with rope) the fill-tube material around the discharge hose, so that the discharge hose does not flop around while filling.

Now that the fill-tubes are prepared, the pumping can get started.

The primary AquaDam started filling and will unroll to the ending bank.

The primary AquaDam only needed a few inches of head above the surrounding water, to allow it to keep it's position and unroll towards the ending bank.

It is important to note that when filling an AquaDam (without turns), use equal pumping power for both fill-tubes simultaneously.

Here we can see ropes going back to shore, which are allowing the AquaDam to build head as it crosses the body of water.

The 16ft tall 300ft long primary AquaDam has almost reached the ending bank.

A great side view of the starting bank, as the primary AquaDam is being deployed.

An excavator is clearing up the ending bank, so the primary AquaDam can make a good seal.

The ending bank has almost been fully cleared.

An excavator is holding back one side of the AquaDam, to build head above the surrounding water depth before reaching the ending bank.

The 16ft tall 33ft wide (fully filled) 300ft long AquaDam continues to fill.

An excavator shifts the log that the AquaDam was rolled up on, to allow the AquaDam to unroll more easily up the ending bank.

The primary AquaDam has reached the ending bank and must now finish filling, to reach it’s maximum height.

The tide is going out as the primary AquaDam is filling. Notice that the water depth on the left is greater in this picture.

The 16ft tall primary AquaDam has reached it’s maximum height.

The starting bank for the first 8ft tall support AquaDam has been prepared.

The support AquaDam is being placed on top of the primary AquaDam, to prepare it for installation.

Workers are removing the outer wrapping off of the 8ft tall 170ft long support AquaDam.

Here workers are unrolling the first support AquaDam (on top of the 16ft primary AquaDam), so that they can position it properly for installation.

Ropes are fastened every 50ft or so, to assist with positioning the support AquaDam.

Ropes were tied on the top seam of the 8ft tall support so it can be held in place while filling, they will be removed when it is completely filled.

The 8ft tall support AquaDam being placed on the side towards the work area (that will be dewatered), where it will help support the primary AquaDam.

Now that the first support AquaDam is in place, it can be prepared to be filled.

Workers are getting ready to place discharge hose into the fill-tubes of the 8ft tall support AquaDam.

After the discharge hose has been placed properly into the fill-tube, the discharge hose can be connected to the pump.

The first 8ft tall support AquaDam has begun filling.

Now the first support AquaDam is pretty much full.

The second 8ft tall support AquaDam is being setup.

Workers unrolling the last AquaDam for this cofferdam system.

The second support AquaDam has been fully unrolled and it will have ropes fastened for positioning, just like the first support AquaDam.

The second support AquaDam being placed on the side towards the work area (that will be dewatered), where it will also help support the primary AquaDam. There will be a gap between the ends of the two 8ft tall AquaDams, that will allow for any water to drain out from between the primary and support AquaDams.

Now that the AquaDam is in the water, it can be prepared to be filled.

Discharge hose being placed in the fill-tubes of the second 8ft tall support AquaDam.

The second 8ft tall support AquaDam is now being filled with water.

The last support AquaDam has been filled to it’s maximum height.

The following morning, we can see the AquaDams are installed and dewatering of the work area is beginning.

Here we can see that the water depth (on the work area side) has dropped dramatically, since the AquaDams have been installed.

In this photo we can actually see the bottom of the first 8ft tall support AquaDam. This photo was taken from the side being dewatered.

We can now see all kinds of obstacles that were hidden under the water.

The work area continues to dewater.

The dewatering work area on the left and the greater river water on the right side.

The work area is almost fully dewatered.

A 16ft tall 33ft wide (fully filled) 300ft long single closed end (SCE) AquaDam used in a line configuration; supported with two 8ft tall 17ft wide SCE AquaDams one 170ft long and the other 80ft long, Interstate 10 Repairs, San Jacinto River, Tidal Influence, Hurricane Harvey Aftermath

This AquaDam cofferdam system was installed in a single (long) day. Take a look at what is coming out from beneath the long 8ft support dam: it’s a boat! The presence of this obstruction was unknown at the time of deployment, but the AquaDam was able to conform around with no apparent damage. The presence of the boat did not extend beneath the primary dam, and so did not affect the seal of the 16ft tall primary dam to the existing soils.