1.) The first 5ft tall 11ft wide 250ft long single closed end (SCE) AquaDam® has been laid out and is being filled with water. Notice the blue discharge hoses going into the fill-tubes of the SCE AquaDam. The starting point (open end) and fill-tubes of a SCE AquaDam® must be elevated higher than the full height of dam along its given path.

2.) The 5ft tall SCE AquaDam® has been started and is being filled with water. The closed end of the first 5ft tall AquaDam® was used as the starting bank for the second dam. The two AquaDams are joined together with a connection collar that is attached to the first dam.

3.) Workers dug out of the riverbed and placed the material (fill) every 20ft along the work area side of the AquaDam. This was done to help keep the AquaDams in place as it was filled.

4.) As the second AquaDam® continues to be filled, workers monitor the roll end and the head that the unrolled length has. After enough head has built in the unrolled length, workers release a few feet and hold the roll end again.

5.) The second 5ft tall SCE AquaDam® continues to fill.

6.) After the 250ft length of the second SCE AquaDam® had unrolled, workers walked out the air bubbles that had accumulated during pumping. Pumps will discharge air along with water sometimes into an AquaDam. The air can easily be walked out, starting at the closed end, and walking the air bubble out towards the fill-tubes.

7.) The first 5ft tall SCE AquaDam® is full and working. Notice the less water depth of the right side and the slight lean towards the right that the AquaDam® has.

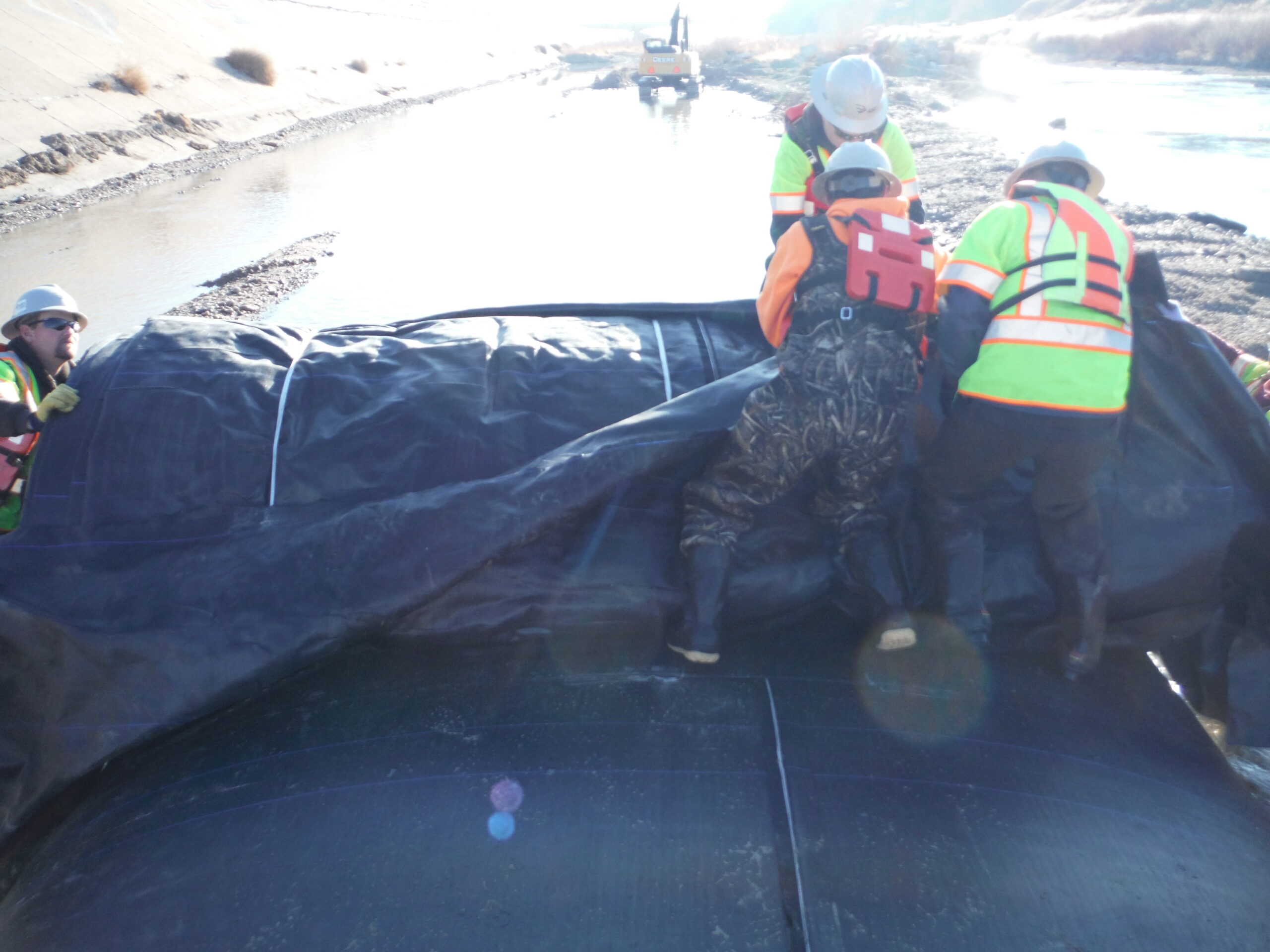

8.) The third 5ft tall SCE AquaDam® has been put at the closed end of the second dam, by the second connection collar. AquaDams are shipped rolled-up like a carpet roll, wrapped in a protective covering, and have lifting ropes/straps. Workers have already removed the lifting ropes and are removing the protective wrapping to expose the rolled up AquaDam® inside.

9.) Workers have made the connection with the second and third AquaDams. Discharge hoses are being inserted into the fill-tubes of the third 5ft tall AquaDam, so that it can be filled with water.

10.) The third 5ft tall SCE AquaDam® is being filled.

11.) The third 5ft tall SCE AquaDam® has reached its ending bank. Now the roll end will need to be tied up to prevent it from unrolling anymore and finish filling the AquaDam.

12.) The fourth 5ft tall 250ft long SCE AquaDam® has been positioned downstream of the first three. This AquaDam® was chosen to close off the downstream end of the work area.

13.) Workers realized that if the fourth AquaDam® was installed the remaining water in the work area would be trapped, so they cut a channel to allow the water to drain out.

14.) The third 5ft tall SCE AquaDam® is pretty much full now and the work area is de-watering.

15.) Looking upstream with the Arkansas River on the left and the work area on the right.

16.) Workers top of the second AquaDam. Notice that the fill-tube of the right side has been folded up and taped to prevent any water from escaping. After workers are done filling the left side they will fold up and tape to the left fill-tube too.

17.) Looking downstream with the Arkansas River on the right and the work area on the left. Notice the water depth differences?

18.) Great job AquaDam!

Four 5ft Tall 11ft Wide (full) 250ft Long Single Closed End (SCE) AquaDams, Arkansas River, River Diversion, Levee Restoration, Line Configuration