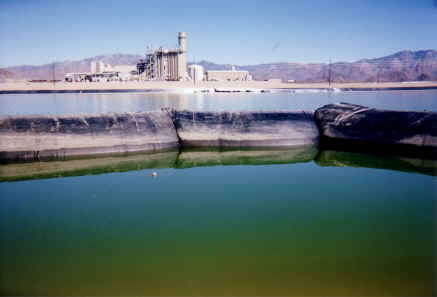

This cooling pond had a tear in the liner. To patch it required dewatering, so the contractor decided on AquaDams. In this picture, a 6' x 100' AquaDam has been started high up the bank and filling has begun.

A rope has been secured to the far side of the board the AquaDam is rolled up on, and as the AquaDam fills this rope is used to pull it into the desired U-shape.

Tension must be kept on the rope the entire time that the AquaDam is filling, or it will naturally try to go straight forward. If adjustments have to be made to the rope, the pumps should be turned off.

Tension must be kept on the rope until the AquaDam is tied back into the bank.

The AquaDam has isolated the work area. Now all that remains is to fill up the AquaDam and dewater the work area.

AquaDam

Once the 6' high AquaDam is completely full, dewatering begins. When the water gets a little bit lower, a 4' high AquaDam will be placed behind the fill end to help support it.

Finally, when the water is only a few inches deep and the tear can be located, a 1.5' high AquaDam will be installed directly around it to keep it completely dry while it is being repaired.

AquaDam

A small pump is used to make sure that the repair area is completely dry.

AquaDam

AquaDam

AquaDam

Once the repair work is completed, the dewatering process is reversed, and the work area is filled with water.

Refilling the work area will make the AquaDams buoyant one at a time so that they can be easily removed.

As each of the AquaDams loses its head pressure and becomes buoyant, it is simply dragged from the water with a piece of equipment.

The AquaDam gradually loses more and more water...

...until it becomes buoyant and floats.

Now the AquaDams can be laid out, rerolled, and used another day!